Calender Process

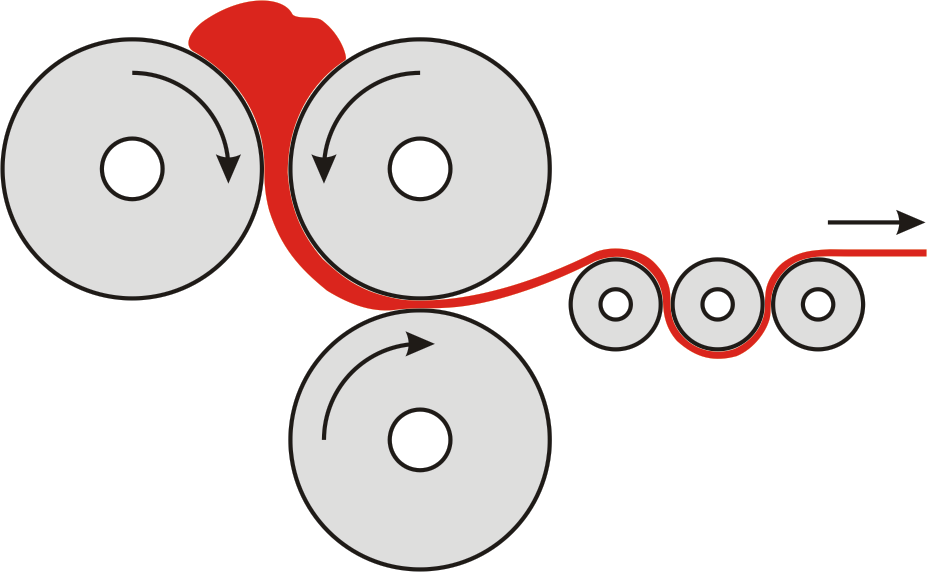

Calender Process - Web calendering finishing is a process of imparting luster and smoothness to a fabric by passing it between pressurized rollers. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Web the calendering process begins by heating and mixing resins, pigments, stabilizers and plasticizers in an industrial mixer. Calendering and milling are sufficiently similar to enable them to be treated together. Here’s an overview of the. Both have been used for many years in the rubber industry, resulting in a. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. Calenders are also used as pre.

Calenders are also used as pre. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Here’s an overview of the. Both have been used for many years in the rubber industry, resulting in a. When carried out on a paper machine, it is called. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. If the moist fabric is passed. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Web calendering is often the last step of the paper manufacturing process, which is targeting to affect paper and board properties.

Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Here’s an overview of the. Calenders are also used as pre. Web calendering is often the last step of the paper manufacturing process, which is targeting to affect paper and board properties. When carried out on a paper machine, it is called. Web calendering finishing is a process of imparting luster and smoothness to a fabric by passing it between pressurized rollers. Web the calendering process aims at enhancing the electrode energy density, and improving the electronic conductivity, and determines the final porous electrode. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Both have been used for many years in the rubber industry, resulting in a. Web calendering, as the final step in electrode production, is a critical process that significantly influences the mechanical and electrochemical properties of the electrode.

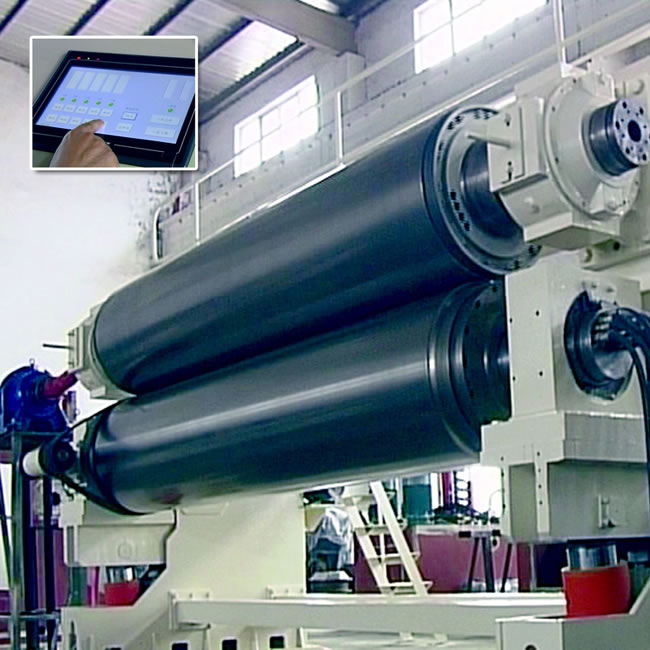

CALENDARING PROCESS ( Industrial Use) YouTube

Here’s an overview of the. Calenders are also used as pre. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. Web.

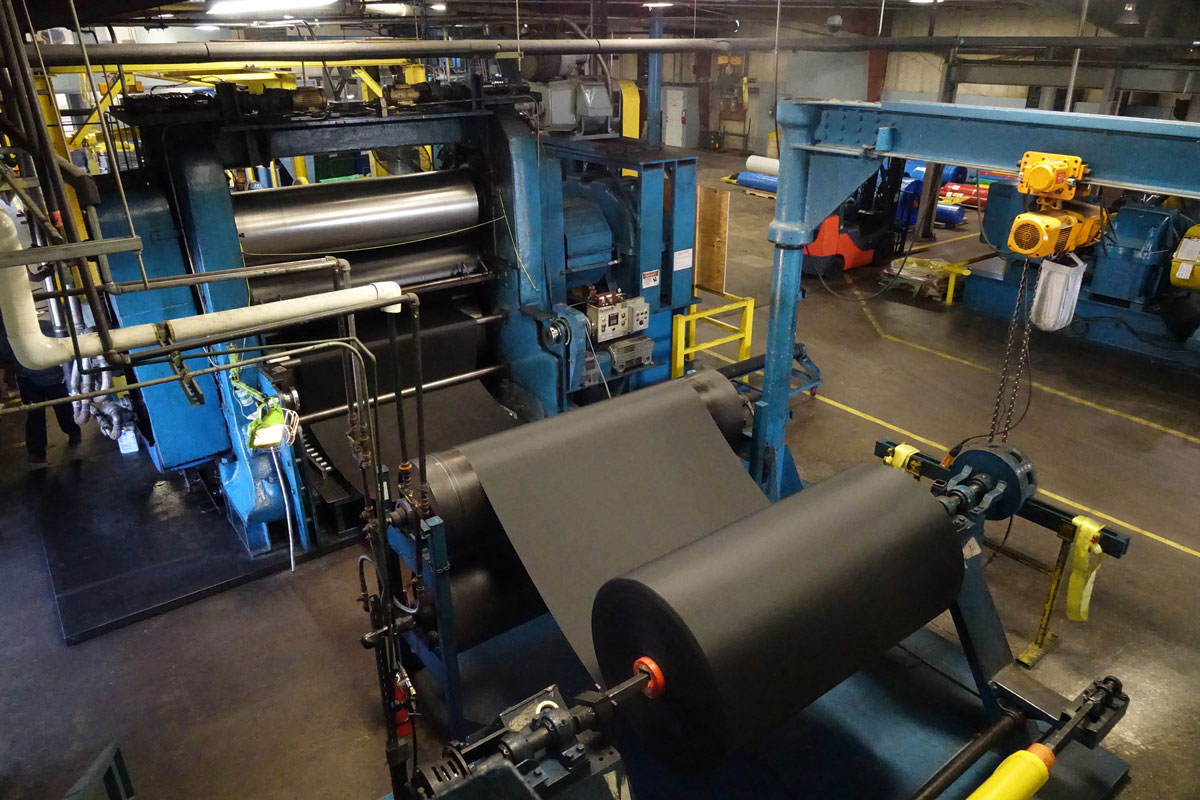

CSI Calendering, Inc Textiles

Web the calendering process aims at enhancing the electrode energy density, and improving the electronic conductivity, and determines the final porous electrode. Web calendering, as the final step in electrode production, is a critical process that significantly influences the mechanical and electrochemical properties of the electrode. Web the calendering process in textiles is a crucial step in fabric finishing that.

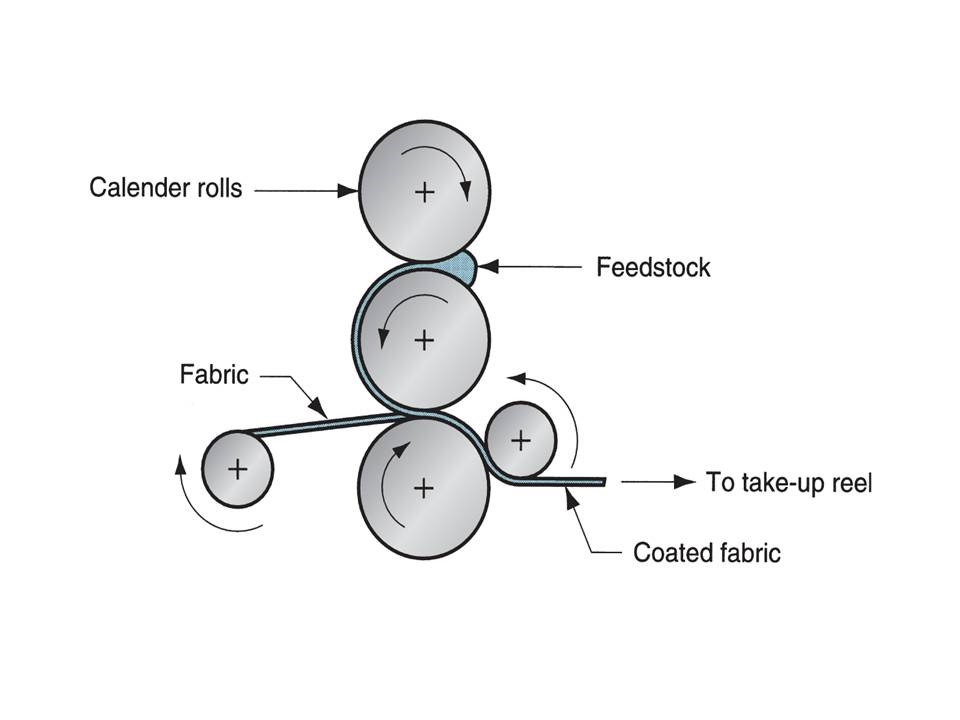

FileCalender process.png Wikimedia Commons

In preparation for calendering, the fabric is folded lengthwise with the front side, or face, inside,. Here’s an overview of the. Calenders are also used as pre. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Web calendering is a type of mechanical levelling and segmenting process.

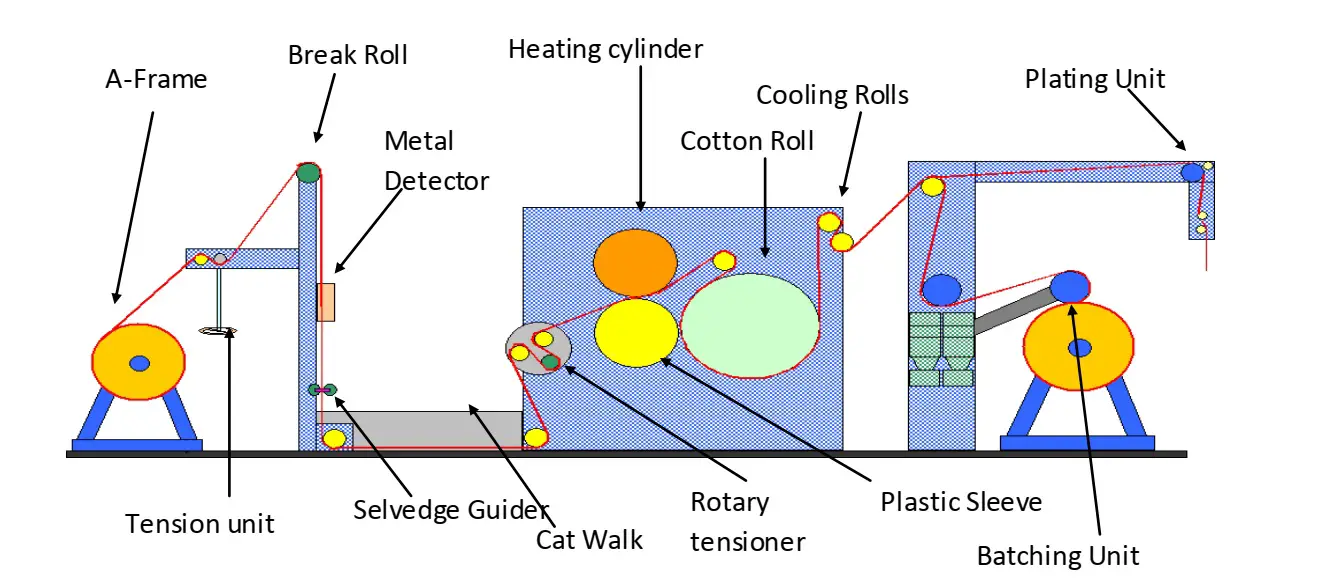

Calendering Factors Effecting Calendering Calendering Machine

Web calendering finishing is a process of imparting luster and smoothness to a fabric by passing it between pressurized rollers. Web the calendering process aims at enhancing the electrode energy density, and improving the electronic conductivity, and determines the final porous electrode. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or.

6 Types of Calendering Process in Textile ! Textile Property

Web calendering, as the final step in electrode production, is a critical process that significantly influences the mechanical and electrochemical properties of the electrode. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics.

Calendering Manufacturing Process Ruth Wright

Web general processing considerations include temperature and pressure controls, calender line speed, dimensions of thickness and width, surface finish, and orientation. Here’s an overview of the. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Web the calendering process begins by heating and mixing resins, pigments, stabilizers.

10 Facts About Calendering in Textile! Textile Property

Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. If the moist fabric is passed. Web general processing considerations include temperature and pressure controls, calender line speed, dimensions of thickness and width, surface finish, and orientation. Web calendering, as the final step in electrode production, is a.

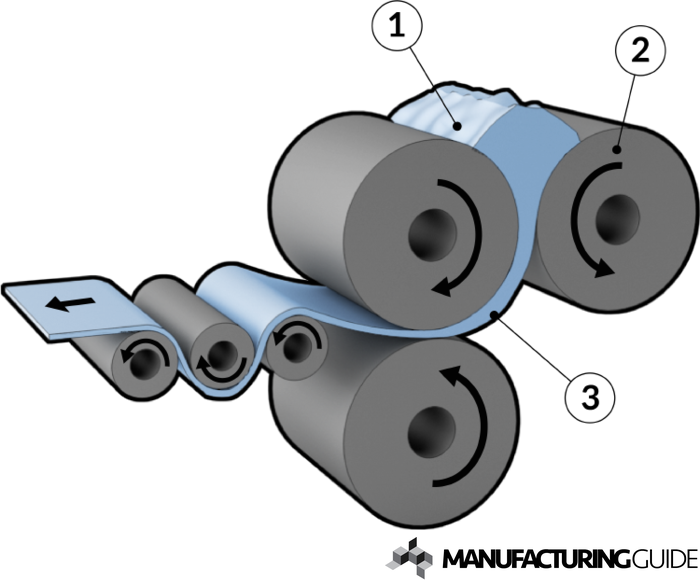

Calendering Find suppliers, processes & material

With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web calendering finishing is a process of imparting luster and smoothness to a fabric by passing it between pressurized rollers. Web general processing considerations include temperature and pressure controls, calender line speed, dimensions of thickness and width, surface finish, and orientation. Web the calendering process begins by.

Calendering Process In Paper Making Lark Gilemette

Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web the calendering process begins by heating and mixing resins, pigments, stabilizers and plasticizers in an industrial mixer. Web calendering is often the last step of the paper manufacturing process, which is targeting to.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

If the moist fabric is passed. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. Calendering and milling are sufficiently similar to enable them to be treated together..

Web Calendering, Shown In Figure 2, Is A Unit Operation Which Compresses The Paper Web Between One Or More Rolling Nips.

Both have been used for many years in the rubber industry, resulting in a. Web general processing considerations include temperature and pressure controls, calender line speed, dimensions of thickness and width, surface finish, and orientation. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture.

In Preparation For Calendering, The Fabric Is Folded Lengthwise With The Front Side, Or Face, Inside,.

Web the calendering process aims at enhancing the electrode energy density, and improving the electronic conductivity, and determines the final porous electrode. Web the calendering process begins by heating and mixing resins, pigments, stabilizers and plasticizers in an industrial mixer. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated.

If The Moist Fabric Is Passed.

Calendering and milling are sufficiently similar to enable them to be treated together. Here’s an overview of the. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Web calendering is often the last step of the paper manufacturing process, which is targeting to affect paper and board properties.

Web Calendering Finishing Is A Process Of Imparting Luster And Smoothness To A Fabric By Passing It Between Pressurized Rollers.

Web calendering, as the final step in electrode production, is a critical process that significantly influences the mechanical and electrochemical properties of the electrode. When carried out on a paper machine, it is called. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Calenders are also used as pre.