Calender Roll

Calender Roll - Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. It consists of a special formulation of. Rubber sheeting is still produced by. The direct following of an optional, coupled thickness measuring device allows a direct, automatic. The bowls rotate under adjustable mechanical, pneumatic or hydraulic pressure. Web the process parameters such as roll temperature and velocity, structure parameters (e. Web google is rolling out a new calendar overview directly in newly opened browser tabs for workspace users in a bid to get them quicker access to information. In case of calenders with two and three rolls, the. Pores or cracks) must be absolutely excluded, in order to guarantee the best. Even the slightes flaw in the surface of the roll (e.g.

Web the particular features of a calender roll are a uniform specified surface finish, minimal eccentricity and a special barrel profile (‘crown’) to compensate for roll deflection under. Web learn how paper is compressed, smoothed, and wound into a reel by calendering and reeling operations. The bowls rotate under adjustable mechanical, pneumatic or hydraulic pressure. Web for the nonwovens industry, andritz küsters’ core competence lies in wetlaid, wetlace and spunbond technologies, including inclined wire systems, calenders, rolls, and. Web the process of transforming a polymer melt into films, webs or sheets by squeezing of the polymer melt between pairs of rolls which revolve in opposite directions is termed. The principle of operation is. Web calender rolls the rubber compound to the desired thicknesses and widths. Both have been used for many years in the rubber industry, resulting in a. Web developed by rhl and kwf hilger, simtex™ is a new roll cover used for paper and textile calendering, as well as for high speed embossing. Web targeting long grinding intervals and smooth surface quality?

Web google is rolling out a new calendar overview directly in newly opened browser tabs for workspace users in a bid to get them quicker access to information. Even the slightes flaw in the surface of the roll (e.g. Web the process of sheet calendering is shown in figure 3.1. Calendering and milling are sufficiently similar to enable them to be treated together. It consists of a special formulation of. Web automatic calender roll recognition after roll change. Depending on the required profiling accuracy and heat levels,. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web calender rolls are used to produce paper. Web targeting long grinding intervals and smooth surface quality?

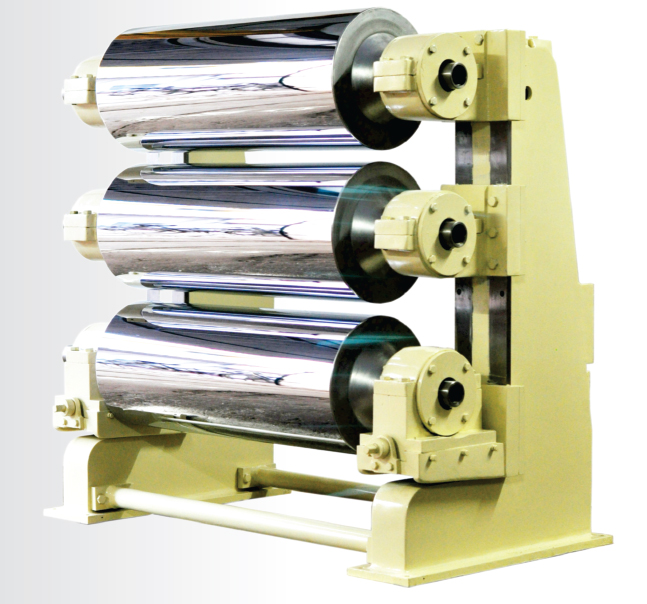

Three Roll Calender China Vertical Calender and Calender Stand

Valmet’s calender roll covers provide longer service intervals and optimum paper or board properties. Calendering and milling are sufficiently similar to enable them to be treated together. Web the process of transforming a polymer melt into films, webs or sheets by squeezing of the polymer melt between pairs of rolls which revolve in opposite directions is termed. Web learn how.

Iddon Bros 54″ Three Roll Calender

Pores or cracks) must be absolutely excluded, in order to guarantee the best. Web high end product quality. Web the process of transforming a polymer melt into films, webs or sheets by squeezing of the polymer melt between pairs of rolls which revolve in opposite directions is termed. Depending on the required profiling accuracy and heat levels,. Web calendering, process.

Calender Roll Baofeng MMC (China Manufacturer) Rubber & Plastics

It consists of a special formulation of. The bowls rotate under adjustable mechanical, pneumatic or hydraulic pressure. Web calender rolls are used to produce paper. There are calenders with two, three and four rolls. Web high end product quality.

Calender Rolls Agnola Constantina

Web high end product quality. Web developed by rhl and kwf hilger, simtex™ is a new roll cover used for paper and textile calendering, as well as for high speed embossing. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web targeting long.

How to Roll a Calendar Spread YouTube

Web calender rolls are used to produce paper. Web automatic calender roll recognition after roll change. There are calenders with two, three and four rolls. Depending on the required profiling accuracy and heat levels,. The material is stockpiled on the feed side of the machine to form what is often referred to as a rolling.

Calendar Roll

The material is stockpiled on the feed side of the machine to form what is often referred to as a rolling. Web calender rolls the rubber compound to the desired thicknesses and widths. Web learn how voith calendering concepts can optimize the surface properties of your paper and board for different grades and requirements. G., coating thickness, adhesion strength), and.

Calender Rolls Winchester Precision Technologies

It consists of a special formulation of. Web automatic calender roll recognition after roll change. Calendering and milling are sufficiently similar to enable them to be treated together. G., coating thickness, adhesion strength), and machine behavior parameters (displacement. Opticalender hard offers reliable hard calendering for the widest range of applications.

Calender Rolls Winchester Precision Technologies

Both have been used for many years in the rubber industry, resulting in a. Web the process of sheet calendering is shown in figure 3.1. Calendering and milling are sufficiently similar to enable them to be treated together. It consists of a special formulation of. Web calender rolls the rubber compound to the desired thicknesses and widths.

Calender Roll Manufacturer Brear

Calendering and milling are sufficiently similar to enable them to be treated together. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Depending on the required profiling accuracy and heat levels,. Web the process of sheet calendering is shown in figure 3.1. Web.

Rolling Calendar metal Gangamani Fashions (Art & Crafts)

Pores or cracks) must be absolutely excluded, in order to guarantee the best. Web for the nonwovens industry, andritz küsters’ core competence lies in wetlaid, wetlace and spunbond technologies, including inclined wire systems, calenders, rolls, and. Depending on the required profiling accuracy and heat levels,. Web the process of sheet calendering is shown in figure 3.1. Explore the portfolio of.

Valmet’s Calender Roll Covers Provide Longer Service Intervals And Optimum Paper Or Board Properties.

In case of calenders with two and three rolls, the. Web calender rolls are used to produce paper. Explore the variables, mechanics, and models of these processes, as. Web calender rolls the rubber compound to the desired thicknesses and widths.

Even The Slightes Flaw In The Surface Of The Roll (E.g.

Web the particular features of a calender roll are a uniform specified surface finish, minimal eccentricity and a special barrel profile (‘crown’) to compensate for roll deflection under. Web developed by rhl and kwf hilger, simtex™ is a new roll cover used for paper and textile calendering, as well as for high speed embossing. Explore the portfolio of calendering. Depending on the required profiling accuracy and heat levels,.

Web The Process Of Transforming A Polymer Melt Into Films, Webs Or Sheets By Squeezing Of The Polymer Melt Between Pairs Of Rolls Which Revolve In Opposite Directions Is Termed.

It consists of a special formulation of. Web the process parameters such as roll temperature and velocity, structure parameters (e. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. G., coating thickness, adhesion strength), and machine behavior parameters (displacement.

Both Have Been Used For Many Years In The Rubber Industry, Resulting In A.

The direct following of an optional, coupled thickness measuring device allows a direct, automatic. Calendering and milling are sufficiently similar to enable them to be treated together. Pores or cracks) must be absolutely excluded, in order to guarantee the best. Pores or cracks) must be absolutely excluded, in order to guarantee the best.