Deep Drawing Aluminum

Deep Drawing Aluminum - This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawn enclosures & precision fabricated sheet metal parts. Web understanding the deep drawing of aluminum: Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. Aluminum unfortunately often gets a. Web deep drawing, the process of turning sheet metal into hollow parts, is a critical production process and from the measurement of certain material properties it can be seen that aluminum has favorable performance when compared to steels. American aluminum company (amalco) offers expert metal forming with a full range of secondary operations. This technique involves applying considerable force to mold a sheet or blank of a relatively malleable alloy into a designated female draw cavity. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides.

To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. Is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups, caps, canisters, instrument housings and shells. Deep draw depth & process. Web understanding the deep drawing of aluminum: Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. Web deep drawing aluminum—not as hard as it looks. Web using stamping or hydroforming, the deep draw processes delivers symmetrical or irregular parts with precise measurements. An ideal product designed for an aluminum stretch draw. This technique involves applying considerable force to mold a sheet or blank of a relatively malleable alloy into a designated female draw cavity.

It is thus a shape transformation process with material retention. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. Web deep drawing aluminum—not as hard as it looks. Is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups, caps, canisters, instrument housings and shells. Web using stamping or hydroforming, the deep draw processes delivers symmetrical or irregular parts with precise measurements. The present study briefs about the current developments in the deep drawing process at the elevated temperature. An ideal product designed for an aluminum stretch draw. Drawing metal & metal forming. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:

Deep drawing Find suppliers, processes & material

This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. Aluminum unfortunately often gets a. Web deep drawing, the process of turning sheet metal into hollow parts, is a critical production process and from the measurement of certain material properties it can be seen that aluminum has.

Deep Drawing New England Metalform, Inc., Precision Metal Stamped

Painting (wet and powder) piercing. Benefits of deep drawn aluminum. It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. The following article provides an overview of the aluminum deep drawing process. The present study briefs about the current developments in the deep drawing process at the elevated temperature.

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

It is thus a shape transformation process with material retention. Deep drawing is a widely used manufacturing technique for aluminum. Web deep drawn enclosures & precision fabricated sheet metal parts. Deep drawn aluminum is also used for heat reduction and as a heat sink. Web the deep drawing process is utilized for the manufacturing of sheet metal components in the.

What is Deep Drawing? Process, Diagram, Advantages & Applications

It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. The following article provides an overview of the aluminum deep drawing process. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. An ideal product designed for an aluminum stretch draw. Deep.

Deep drawing of sheet metal

American aluminum company (amalco) offers expert metal forming with a full range of secondary operations. Web the resulting parts and products are both strong and lightweight. Deep drawn aluminum is also used for heat reduction and as a heat sink. Amalco works with all metals. Deep drawing is a widely used manufacturing technique for aluminum.

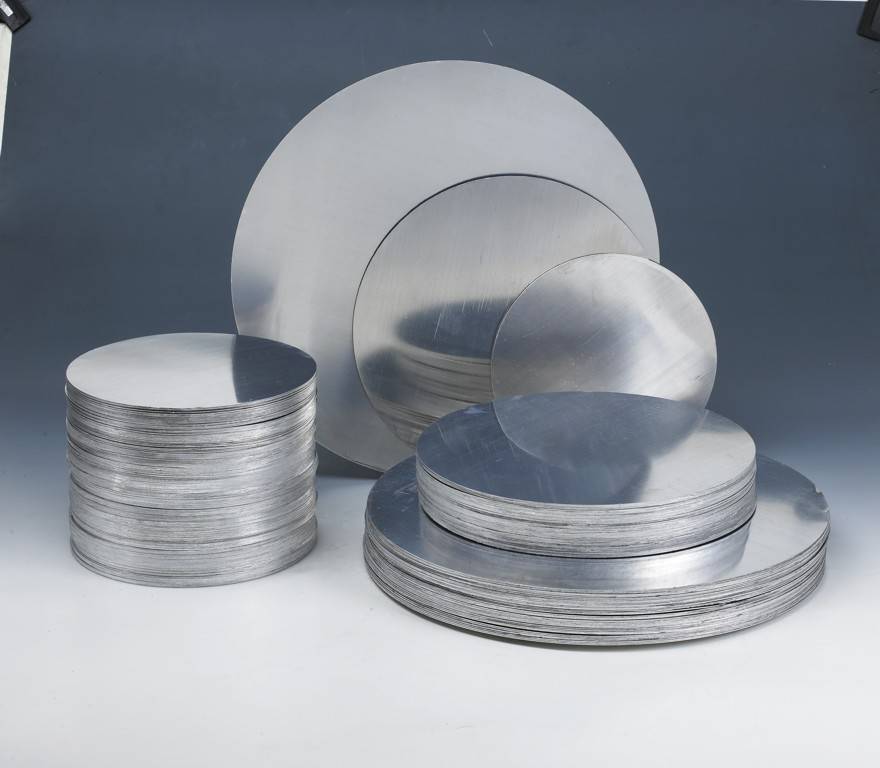

Deep Drawing Aluminum Sheet Circle 1050 1060 Aluminum Plate ASTM B209

Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. It is thus a shape transformation process with material retention. Web the resulting parts and products are both strong and lightweight. Benefits of deep drawn aluminum. The metal thickness, the metal type, and the blank size.

best deep drawing process, by chris YouTube

Drawing metal & metal forming. Web understanding the deep drawing of aluminum: Web deep drawing friction is a key boundary condition for controlling the forming quality of aluminium alloy parts. The metal thickness, the metal type, and the blank size. This technique involves applying considerable force to mold a sheet or blank of a relatively malleable alloy into a designated.

Deep Drawing Aluminum Circle Summary Resource Co., Ltd

This technique involves applying considerable force to mold a sheet or blank of a relatively malleable alloy into a designated female draw cavity. However, due to the oxidation and adhesion tendency of aluminium alloys, the tribological situations of aluminium alloy deep drawing (aadd) system is more complicated than those of traditional deep drawing of steel sheets. American aluminum company (amalco).

Deep Drawn Aluminum Stampings from Charles Richter

Aluminum unfortunately often gets a. It is thus a shape transformation process with material retention. Web the deep drawing process is utilized for the manufacturing of sheet metal components in the automobile and aerospace industries. Is an industry leader of low and high volume manufacturing of precision fabricated & deep drawn sheet metal parts, deep drawn cans, cases, boxes, cups,.

Deep Drawn Methodology and Its Benefits

However, due to the oxidation and adhesion tendency of aluminium alloys, the tribological situations of aluminium alloy deep drawing (aadd) system is more complicated than those of traditional deep drawing of steel sheets. This forming process is a highly cost effective and fast way to form both large and small production runs. This process stretches the aluminum into a shape.

Web Understanding The Deep Drawing Of Aluminum:

Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Painting (wet and powder) piercing. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. However, due to the oxidation and adhesion tendency of aluminium alloys, the tribological situations of aluminium alloy deep drawing (aadd) system is more complicated than those of traditional deep drawing of steel sheets.

Web The Resulting Parts And Products Are Both Strong And Lightweight.

Deep drawing is a widely used manufacturing technique for aluminum. Web deep drawing aluminum—not as hard as it looks. Typical end products include hollow cylindrical or rectangular components with straight, curved, or tapered sides. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch.

Benefits Of Deep Drawn Aluminum.

Web deep drawing friction is a key boundary condition for controlling the forming quality of aluminium alloy parts. It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. Metal & alloy selection for metal drawing and hydroforming. This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components.

Our Deep Drawn Aluminum Metal Stampings And Aluminum Forms Are Commonly Used In The Aerospace, Automotive, Water Treatment, Power Storage, Battery, And Pharmaceutical Industries.

Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. The metal thickness, the metal type, and the blank size. This technique involves applying considerable force to mold a sheet or blank of a relatively malleable alloy into a designated female draw cavity. An ideal product designed for an aluminum stretch draw.