Sheet Metal Bend Radius

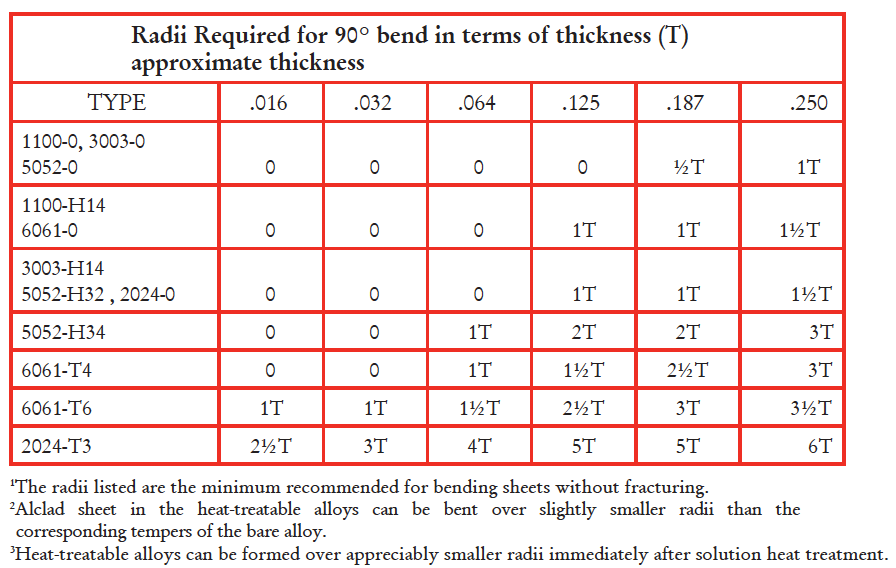

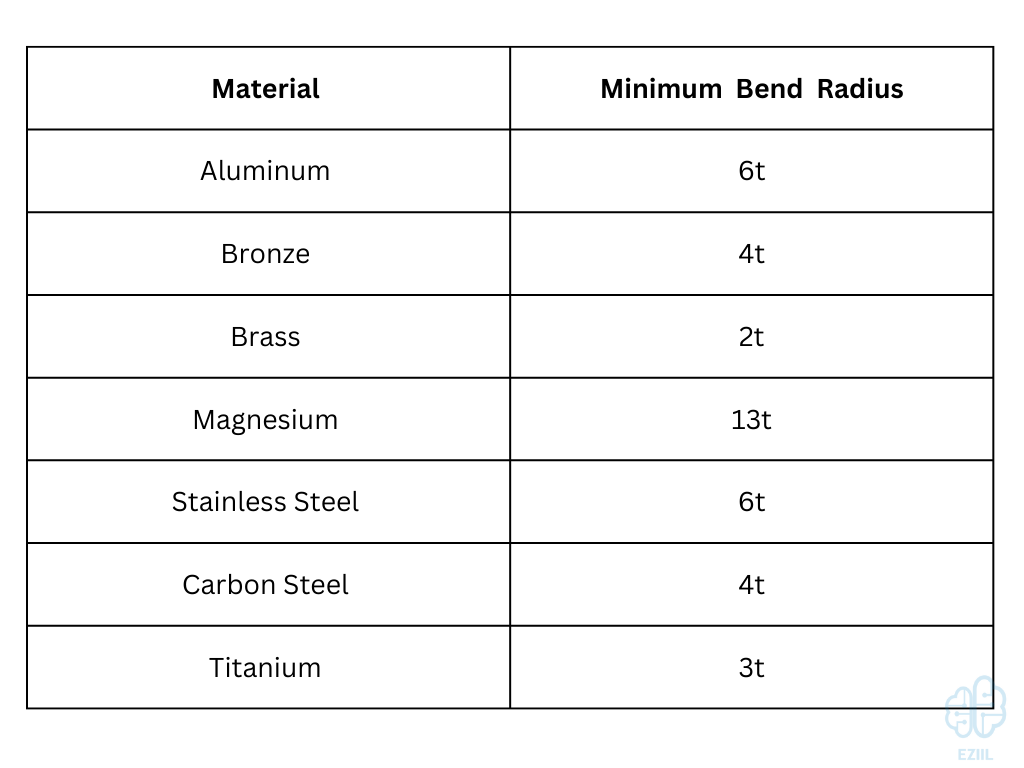

Sheet Metal Bend Radius - Refer to table (s) for your choice of material. Here again, though, we’ve dialed in our. Consider what minimum bend size you. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Web to use the tables below: Web minimum bend radius. 1.5 times the thickness of the sheet. 1 time the thickness of the sheet. Refer to the first column to choose your material thickness.

Web to use the tables below: Web minimum bend radius. 1 time the thickness of the sheet. Consider what minimum bend size you. Refer to table (s) for your choice of material. Refer to the first column to choose your material thickness. Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. 1.5 times the thickness of the sheet. Here again, though, we’ve dialed in our. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”.

Web minimum bend radius. Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Refer to the first column to choose your material thickness. Refer to table (s) for your choice of material. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. 1 time the thickness of the sheet. Here again, though, we’ve dialed in our. Web to use the tables below: Consider what minimum bend size you. 1.5 times the thickness of the sheet.

Engineering First Principles (engineering_first_principles) en

Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Web minimum bend radius. Web to use the tables below: 1.5 times the thickness of the sheet. Consider what minimum bend size you.

How To Bend A Radius In Sheet Metal? Unity Manufacture

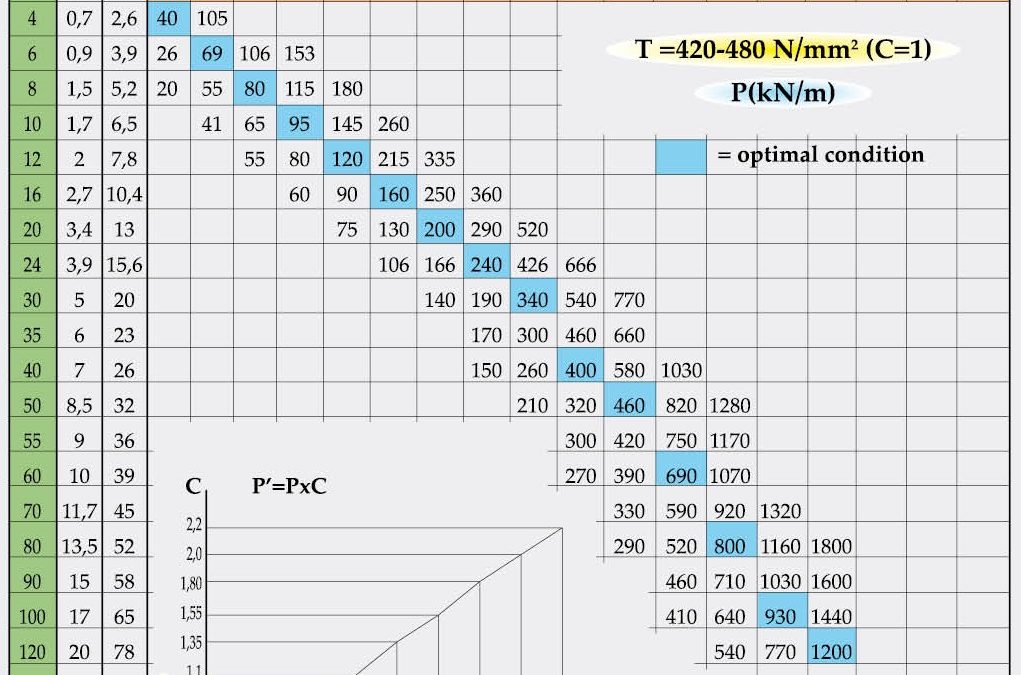

Web minimum bend radius. 1.5 times the thickness of the sheet. Refer to table (s) for your choice of material. Consider what minimum bend size you. Refer to the first column to choose your material thickness.

costante erba Fiorire sheet metal bend radius chart angolo suolo

Web to use the tables below: Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. 1.5 times the thickness of the sheet. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Refer to table (s) for.

Una frase Finora microfono sheet metal bending chart Esercizio labbra

Web minimum bend radius. Here again, though, we’ve dialed in our. Web to use the tables below: Refer to the first column to choose your material thickness. 1 time the thickness of the sheet.

Sheet Metal Bend Radius Full Guide Chart

Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Web to use the tables below: 1.5 times the thickness of the sheet. 1 time the thickness of the sheet. Refer to the first column to choose your material thickness.

costante erba Fiorire sheet metal bend radius chart angolo suolo

1.5 times the thickness of the sheet. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Web to use the tables below: Web minimum bend radius. Consider what minimum bend size you.

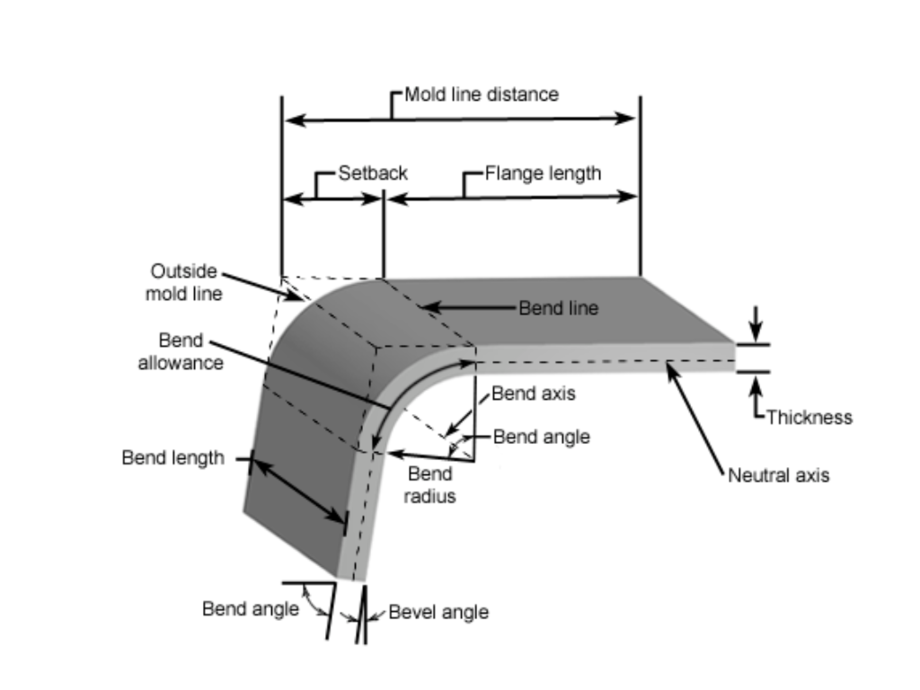

Sheet Metal Enclosure Design Key Enclosure Design Tips rapiddirect

Web to use the tables below: Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Here again, though, we’ve dialed in our. Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Web minimum bend radius.

Una frase Finora microfono sheet metal bending chart Esercizio labbra

Web to use the tables below: Refer to the first column to choose your material thickness. Consider what minimum bend size you. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. 1.5 times the thickness of the sheet.

Sheet Metal Bend Radius Full Guide Chart

1 time the thickness of the sheet. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Consider what minimum bend size you. 1.5 times the thickness of the sheet. Web minimum bend radius.

The sheet metal stretchbending with bending radius R die (a) the

1 time the thickness of the sheet. Consider what minimum bend size you. Web minimum bend radius. Web the sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”.

1.5 Times The Thickness Of The Sheet.

Web your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Web minimum bend radius. Refer to table (s) for your choice of material. Here again, though, we’ve dialed in our.

Web The Sheet Metal Bending Radius Is A Critical Value In Sheet Metal Drawing That Can Be Difficult To Determine During The Actual Processing.

1 time the thickness of the sheet. Consider what minimum bend size you. Refer to the first column to choose your material thickness. Web to use the tables below: