Welding Drawing

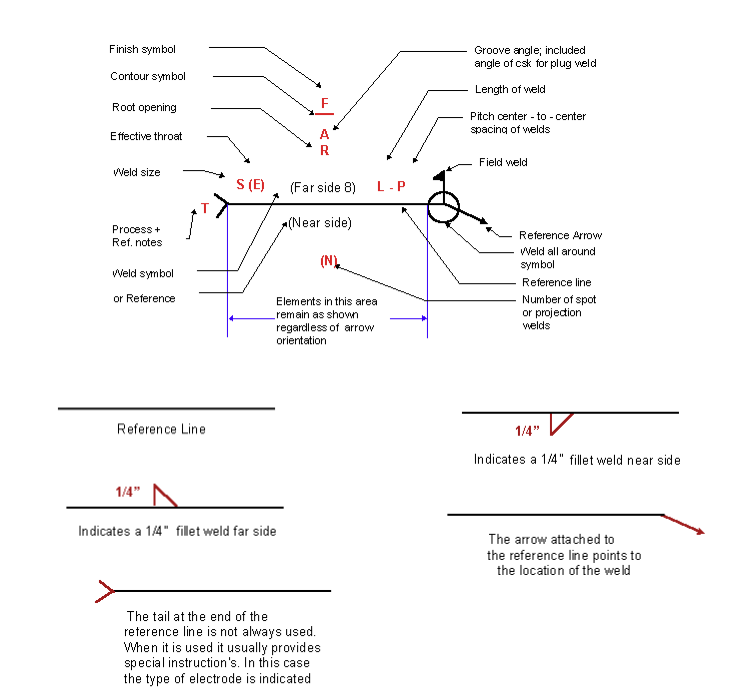

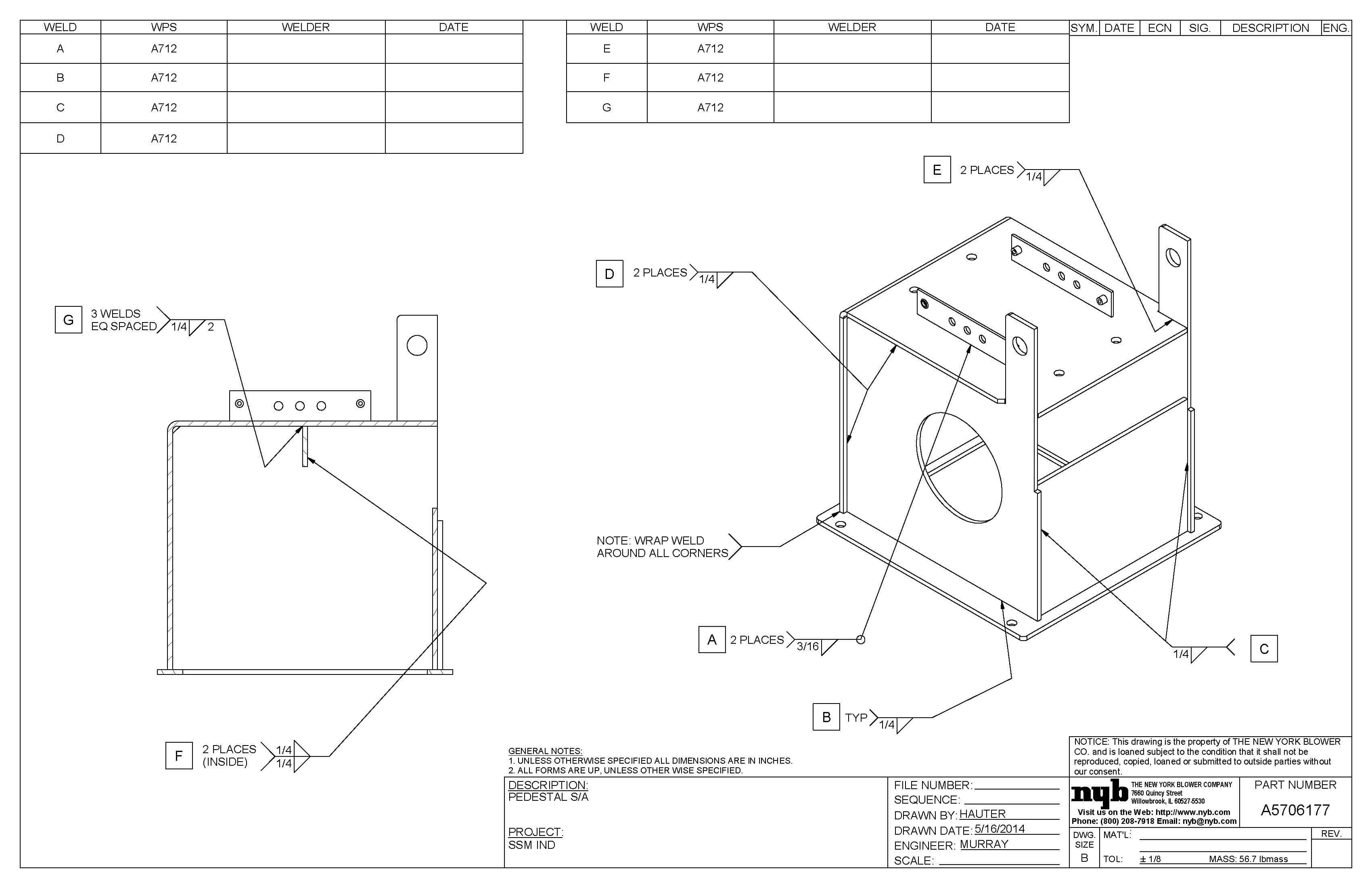

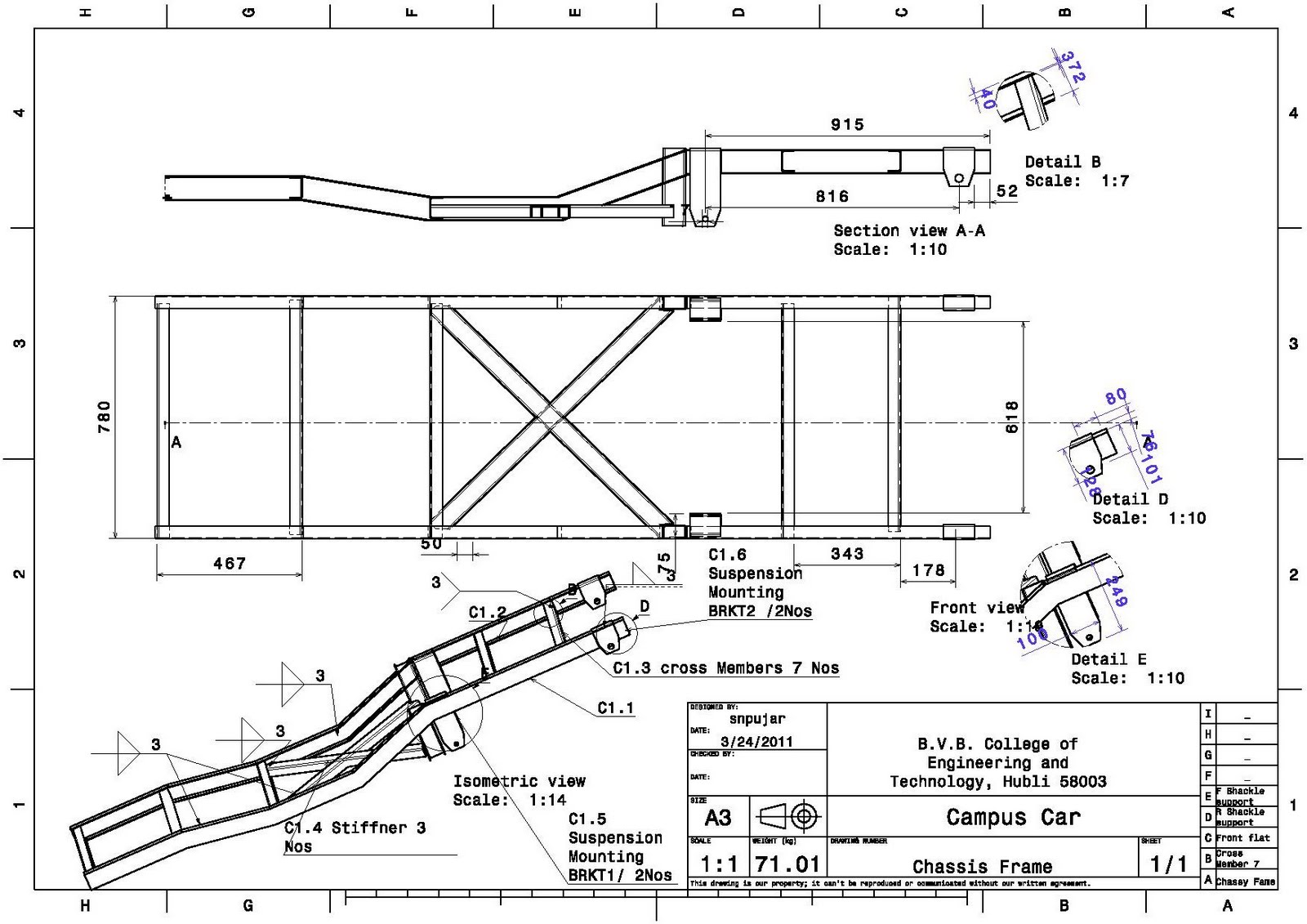

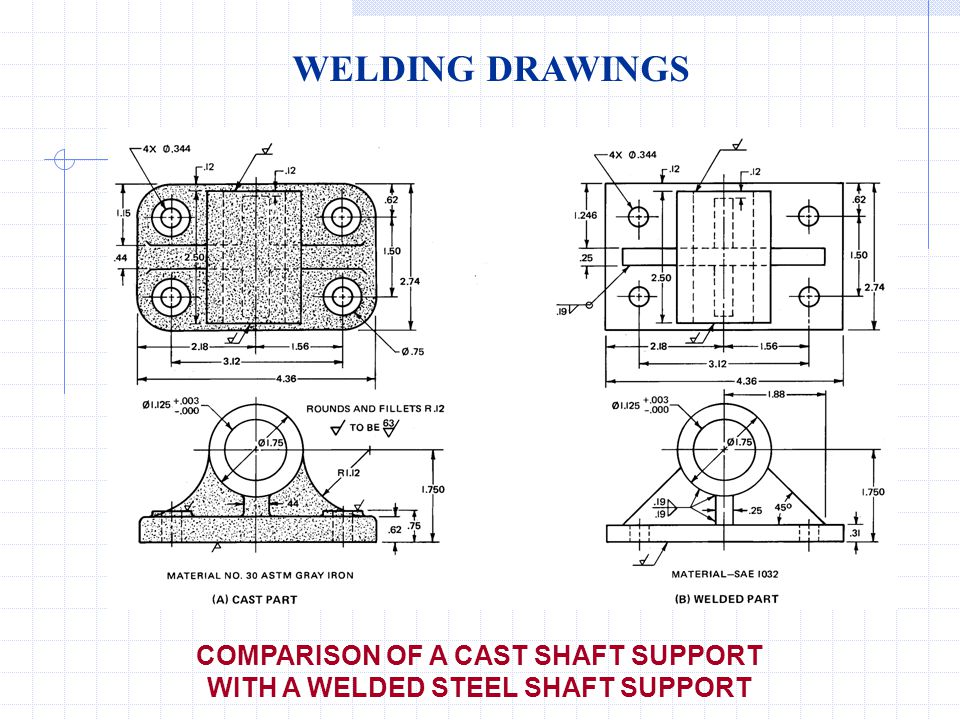

Welding Drawing - All the information you need as a welder is in the welding symbol. These are symbols used to indicate welding methods, weld form, and weld size, among other technical content on a drawing. The main purpose of welding blueprints is to provide clear and accurate instructions to the welder so that they can create a safe and sound weld joint. Web home » welders. When you see an engineering fabrication drawing, you will notice several welding symbols on the drawing. Weld symbols on drawings should be understood through the design and manufacturing pipeline, including shop floor personnel. We explain the basics of weld symbols: In this article, we try to explain some basic weld symbols and what’s their use. Web welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality requirements for the fabrication or construction drawing. The use of symbols can significantly reduce the time needed to complete a drawing compared to drawing the weld as it will appear.

Web welding symbols, also referred to as weld callouts and welding drawing symbols, contain information pertinent to the weld as previously mentioned. Weld symbols and welding symbols enable the designer to communicate and convey the required welding details to. Welders live by the 1/16 th rule—meaning their welds can be larger or smaller than what is specified by no more than 1/16 th of an inch. Web home » welders. Their structure, what different lines mean, and what standards there are. The welding symbols, dimensions, and notes. The main purpose of welding blueprints is to provide clear and accurate instructions to the welder so that they can create a safe and sound weld joint. What is a welding symbol & its meaning? Every welding symbol that you see will have an arrowhead which points to the location where you need to make the weld. Concept of the welding symbols, importance and significance of welding symbols and how to understand these symbols in the drawing.

Points to the general location of the weld. In providing educational programs and opportunities, the college of lake county is committed to maintaining an environment free from harassment and discrimination and will not. The arrow is connected to what we call a leader line. It is essential that the 'rules' of the standard used are correctly applied by drawing office personnel. Welding symbols are used to indicate desired welding & brazing details on the fabrication drawings. Web welding symbols, also referred to as weld callouts and welding drawing symbols, contain information pertinent to the weld as previously mentioned. Web weld symbols are a very useful way of communicating welding requirements from the design office to the shop floor. Weld symbols on drawings should be understood through the design and manufacturing pipeline, including shop floor personnel. If you’re welder you must know how to read welding blueprints to understand welding diagrams. The arrow may point up or down.

Understanding the Welding Symbols in Engineering Drawings Safe Work

Web august 11, 2022. Below is a comprehensive list of what one can expect to see on a welding symbol, as well as an example image and list of options for each aspect of the welding symbol. When you see an engineering fabrication drawing, you will notice several welding symbols on the drawing. The purpose of engineering drawing weld symbols.

Welding Drawing at GetDrawings Free download

All the information you need as a welder is in the welding symbol. The main purpose of welding blueprints is to provide clear and accurate instructions to the welder so that they can create a safe and sound weld joint. Web april 8, 2022 by sandeep kumar. This document recognizes that there are two different approaches in the global market.

Welding Drawing at Explore collection of Welding

Web learn how to weld with classes and video courses from arc academy. This is where the details are placed about the type of weld and the specific location. If you’re welder you must know how to read welding blueprints to understand welding diagrams. Web april 8, 2022 by sandeep kumar. A complete guide to weld symbols:

Weld Map Drawing Example at GetDrawings Free download

The arrow may point up or down. This symbol is a simple platform for displaying the characteristics and surrounding details for your welds. Web using welding symbols to indicate necessary welding information on engineering drawings offers several advantages: Welding blueprints typically consist of three parts: This document recognizes that there are two different approaches in the global market to designate.

Welding Drawing at Explore collection of Welding

Welding blueprints typically consist of three parts: Web welding symbols are drawn with a specific structure that describes the direction and type of weld to make. The purpose of engineering drawing weld symbols is to create a channel of communication between designers, engineers, and manufacturers. The use of symbols can significantly reduce the time needed to complete a drawing compared.

Welder Drawing at GetDrawings Free download

What is a welding symbol & its meaning? Welders live by the 1/16 th rule—meaning their welds can be larger or smaller than what is specified by no more than 1/16 th of an inch. This is where the details are placed about the type of weld and the specific location. The welding symbol is a graphical representation that is.

Welding Drawing at Explore collection of Welding

The welding symbols, dimensions, and notes. The main purpose of welding blueprints is to provide clear and accurate instructions to the welder so that they can create a safe and sound weld joint. The arrow is connected to what we call a leader line. This is where the details are placed about the type of weld and the specific location..

Welder SVG Welding Vector Welder Vector Welder File for Etsy

Web aisc home | american institute of steel construction If you’re welder you must know how to read welding blueprints to understand welding diagrams. Welding blueprints typically consist of three parts: Welding symbols are used to indicate desired welding & brazing details on the fabrication drawings. The use of symbols can significantly reduce the time needed to complete a drawing.

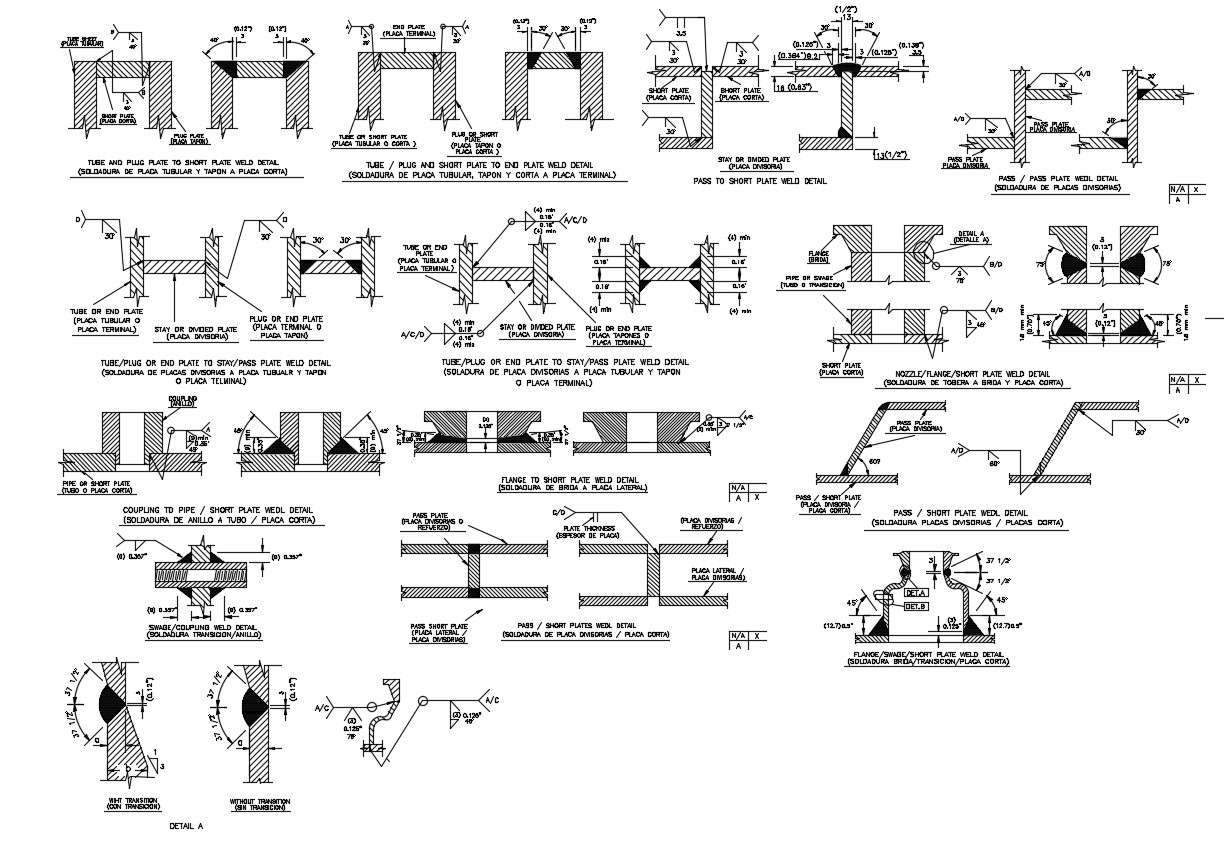

Welding detail in dwg file Cadbull

Web using welding symbols to indicate necessary welding information on engineering drawings offers several advantages: Weld symbols on drawings should be understood through the design and manufacturing pipeline, including shop floor personnel. The use of symbols can significantly reduce the time needed to complete a drawing compared to drawing the weld as it will appear. Learning and knowing your welding.

Weld. Scheme of Welding Two Parts. Vector Illustration. Stock Vector

Every welding symbol that you see will have an arrowhead which points to the location where you need to make the weld. The main purpose of welding blueprints is to provide clear and accurate instructions to the welder so that they can create a safe and sound weld joint. This is where the details are placed about the type of.

We Explain The Basics Of Weld Symbols:

What is a welding symbol & its meaning? All the information you need as a welder is in the welding symbol. Web aisc home | american institute of steel construction Learning and knowing your welding symbols well is equally important as learning to weld properly.

This Is Where The Details Are Placed About The Type Of Weld And The Specific Location.

This symbol is a simple platform for displaying the characteristics and surrounding details for your welds. This document recognizes that there are two different approaches in the global market to designate the arrow side and other side on drawings, and allows for either to be used in isolation, to suit a particular market need. The arrow is connected to what we call a leader line. Weld symbols and welding symbols enable the designer to communicate and convey the required welding details to.

Web Welding Symbols Are The Integral Part And The Basic Requirements For Fabrication As They Provide Vital Information For The Welding Joint Location, Weld Size (Throat Or Leg Length, Depth Of Penetration) & Length, Weld Type & Quality Requirements For The Fabrication Or Construction Drawing.

Their structure, what different lines mean, and what standards there are. The use of symbols can significantly reduce the time needed to complete a drawing compared to drawing the weld as it will appear. Welding blueprints typically consist of three parts: When you see an engineering fabrication drawing, you will notice several welding symbols on the drawing.

The Purpose Of Engineering Drawing Weld Symbols Is To Create A Channel Of Communication Between Designers, Engineers, And Manufacturers.

Welders live by the 1/16 th rule—meaning their welds can be larger or smaller than what is specified by no more than 1/16 th of an inch. Web welding symbols, also referred to as weld callouts and welding drawing symbols, contain information pertinent to the weld as previously mentioned. Concept of the welding symbols, importance and significance of welding symbols and how to understand these symbols in the drawing. Welding symbols guide welders in preparing, welding, and finishing weld joints.